Introduction: Good Isn't Always Good Enough

You've invested in a high-efficiency chiller plant. The design is robust, the equipment is sized correctly, and your operators follow best-in-class SOPs. You may even have a Building Management System (BMS) and a Central Plant Manager (CPM) in place.

Your plant runs smoothly, comfort complaints are rare, and your energy efficiency metrics look impressive.

But here's the reality most facility teams don't see: even the best-run plants typically leave 10–15% of potential energy savings untapped. That "last ounce" of inefficiency quietly inflates your energy bills and your building's carbon footprint, day after day.

This is where Chiller Plant Optimisation (CPO) becomes your final frontier for HVAC energy efficiency.

Design Gives You a Strong Start

A well-engineered HVAC system is the foundation of building efficiency. When chillers are correctly sized for base and peak loads, pumps and cooling towers are chosen with proper headroom, and the piping network is balanced to maintain stable flow rates, you create a plant capable of delivering excellent performance right out of the gate.

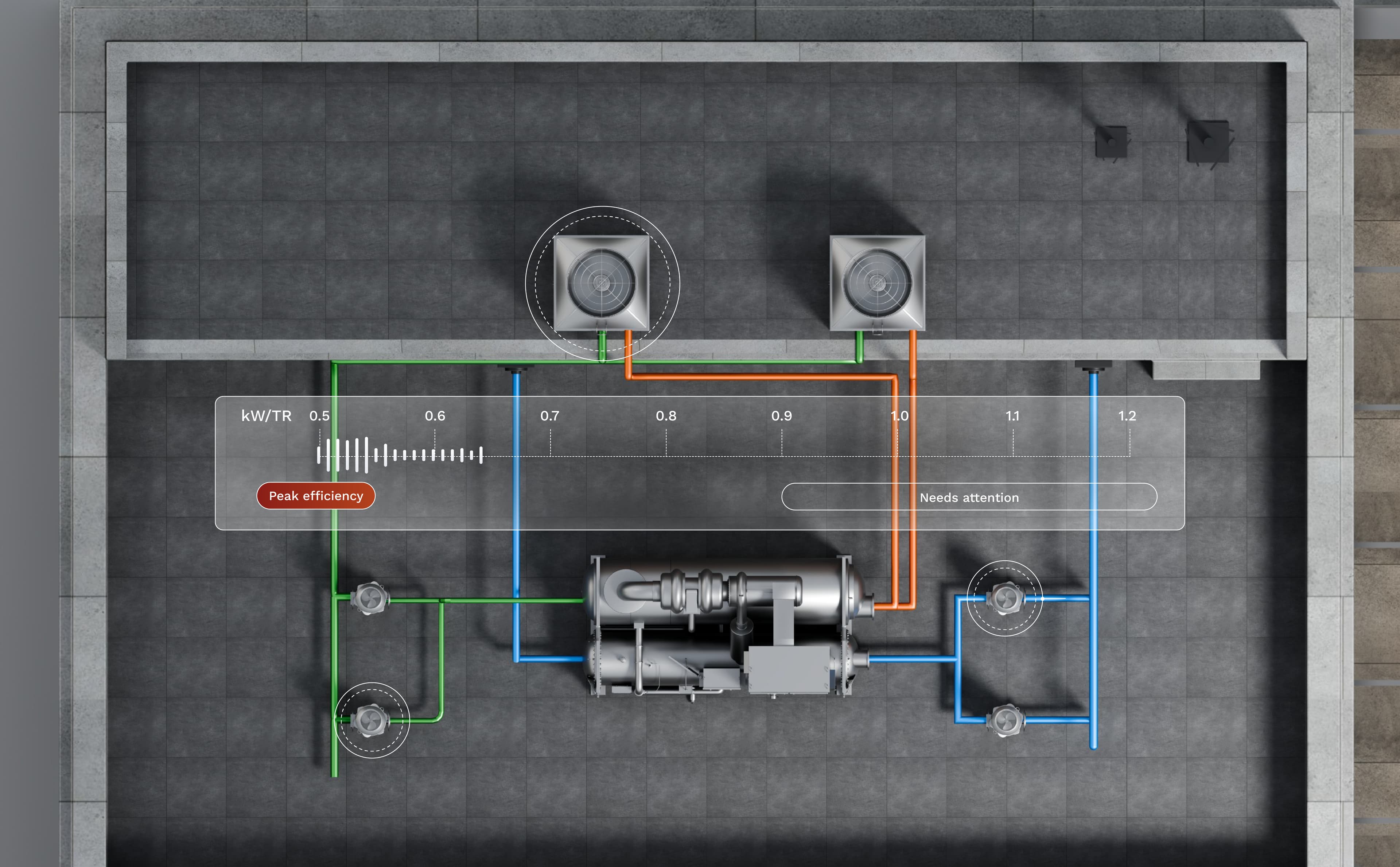

With just a solid design and commissioning effort, most commercial buildings achieve 0.9–1.0 kW/TR — a performance range that meets ASHRAE and ECBC benchmarks and sets a strong baseline for chiller efficiency.

Discipline Pushes You Further

Design may give you a good starting point, but disciplined operations and maintenance are what sustain and improve energy efficiency over time. Regular tube cleaning, chemical water treatment, and sensor calibration keep equipment in top form. Well-trained operators can ensure chillers are sequenced correctly, runtime is evenly distributed, and preventive maintenance tasks are done on schedule.

With this level of commitment, chiller plants can push performance down to ~0.7 kW/TR, which is widely considered top-tier in the industry for HVAC optimization. At this point, you're running a well-oiled machine.

But this is also where you hit a natural ceiling in chiller plant performance.

The Plateau Problem

Even with the best equipment and the most diligent operations team, buildings are dynamic, not static. Cooling loads fluctuate minute by minute, driven by weather, time of day, and occupancy. Traditional BMS and CPM systems, however, are configured with fixed sequences and pre-programmed setpoints.

This mismatch creates a performance gap. Chillers may continue running even after the load has dropped. Pumps might run at unnecessarily high speeds because no one has adjusted their VFD setpoints in months. Towers may reject heat less efficiently because fan speeds don't adapt to changing wet-bulb conditions.

This isn't mismanagement — it's simply the limit of human intervention and static control logic. The result is a plant that is "very good" but never truly optimised every minute of operation for peak efficiency.

Bringing Intelligence Into the Equation

This is where DeJoule's Chiller Plant Optimizer (CPO) comes into play — bridging the gap between well-run and peak-performing plants.

Rather than following a fixed logic set at commissioning, CPO continuously analyses real-time data from your BMS, CPM, and sensors. It uses this information to dynamically choose the most efficient combination of chillers, pumps, and cooling towers for the current load conditions.

More importantly, it goes beyond equipment selection: CPO modulates chilled water setpoints, condenser water temperatures, pump frequencies, and fan speeds every few seconds, keeping your plant operating at its true sweet spot for maximum energy efficiency.

Because CPO is built on a hybrid Edge + Cloud architecture, it executes decisions locally for instant responsiveness and uses cloud analytics to refine its machine learning models over time. This means your chiller plant doesn't just stay efficient — it gets smarter with every passing season through AI-powered optimization.

The Payoff: Peak Efficiency, Every Minute

By eliminating guesswork and conservative operating habits, CPO delivers measurable results for building energy management:

Lower energy bills: Extracts the last 10–15% of hidden energy savings, often worth several lakhs annually for a large hospital or commercial office building.

Lower carbon emissions: Every kWh saved prevents ~0.82 kg of CO₂, helping you meet sustainability targets and achieve green building certification.

Extended equipment life: Balances runtime across all chillers and pumps, reducing overuse of any single asset and improving HVAC system reliability.

Reduced operator workload: Your team monitors performance instead of constantly firefighting or making manual adjustments to building automation systems. Lower energy bills: Extracts the last 10–15% of hidden energy savings, often worth several lakhs annually for a large hospital or commercial office building.

In short, CPO turns your already-efficient plant into a true high-performance asset through intelligent automation.

Closing Thoughts

Great design and disciplined operations are crucial for HVAC efficiency — but they only take you so far. To go beyond the limits of static control logic and human intervention, you need a layer of intelligence that continuously tunes your plant to the building's actual needs using real-time optimization.

DeJoule's Chiller Plant Optimiser does exactly that, helping you achieve peak efficiency every operational minute, without compromising comfort or reliability through advanced building automation.

Frequently Asked Questions

Q1: What is a good kW/TR for a chiller plant?

A well-designed and well-maintained chiller plant typically achieves 0.9–1.0 kW/TR, while plants with excellent SOPs can push chiller efficiency to around 0.7 kW/TR. Beyond this point, intelligent automation such as DeJoule's Chiller Plant Optimiser is required to extract the last 10–15% of hidden energy savings and improve HVAC performance.

Q2: Why does efficiency plateau even in a well-run plant?

Because most BMS and CPM systems rely on fixed logic and setpoints, they can't respond dynamically to minute-by-minute load changes, weather shifts, and equipment health drifts. This creates a "performance ceiling" that only adaptive, real-time optimisation through AI-powered controls can overcome.

Q3: How does a Chiller Plant Optimizer improve efficiency?

A CPO uses real-time data, machine learning, and dynamic equipment selection to continuously adjust chilled water setpoints, pump speeds, and tower operation — delivering peak performance every minute without sacrificing comfort or reliability. This intelligent control system enables maximum energy savings for commercial HVAC systems.

You've come this far. Let DeJoule take you the rest of the way with smart building technology.

Explore Chiller Plant Optimizer →