For decades, HVAC systems in Indian buildings have operated on a paradox. They are the single largest consumers of energy, yet the least intelligently controlled. Hospitals that never sleep, IT campuses running thousands of servers, airports handling millions of passengers, and commercial towers fighting Delhi's 48°C summers—all of them depend on HVAC systems whose performance is often governed by static rules, outdated assumptions, or operator intuition. As energy prices rise, climate patterns intensify, ESG reporting becomes mandatory, and uptime expectations tighten, this old operating model is running out of road.

A quiet revolution, however, is reshaping how buildings breathe, cool, and operate. Driven by IoT, AI, automation, cloud analytics, and integrated building management strategies, intelligent HVAC control is transforming HVAC systems from mechanical workhorses into adaptive, data-driven, autonomous systems that continuously optimize comfort, energy efficiency, and operational reliability. For India, where climatic extremes are worsening, energy intensity remains high, and commercial building stock is expanding rapidly, this transition is not a technological luxury; it is an operational necessity.

This guide explains how intelligent HVAC control works, why building automation is now the cornerstone of high-performing buildings, and what future-ready organizations must embrace to lead in a world where buildings are becoming intelligent ecosystems.

The Rise of Intelligent HVAC: What It Actually Means

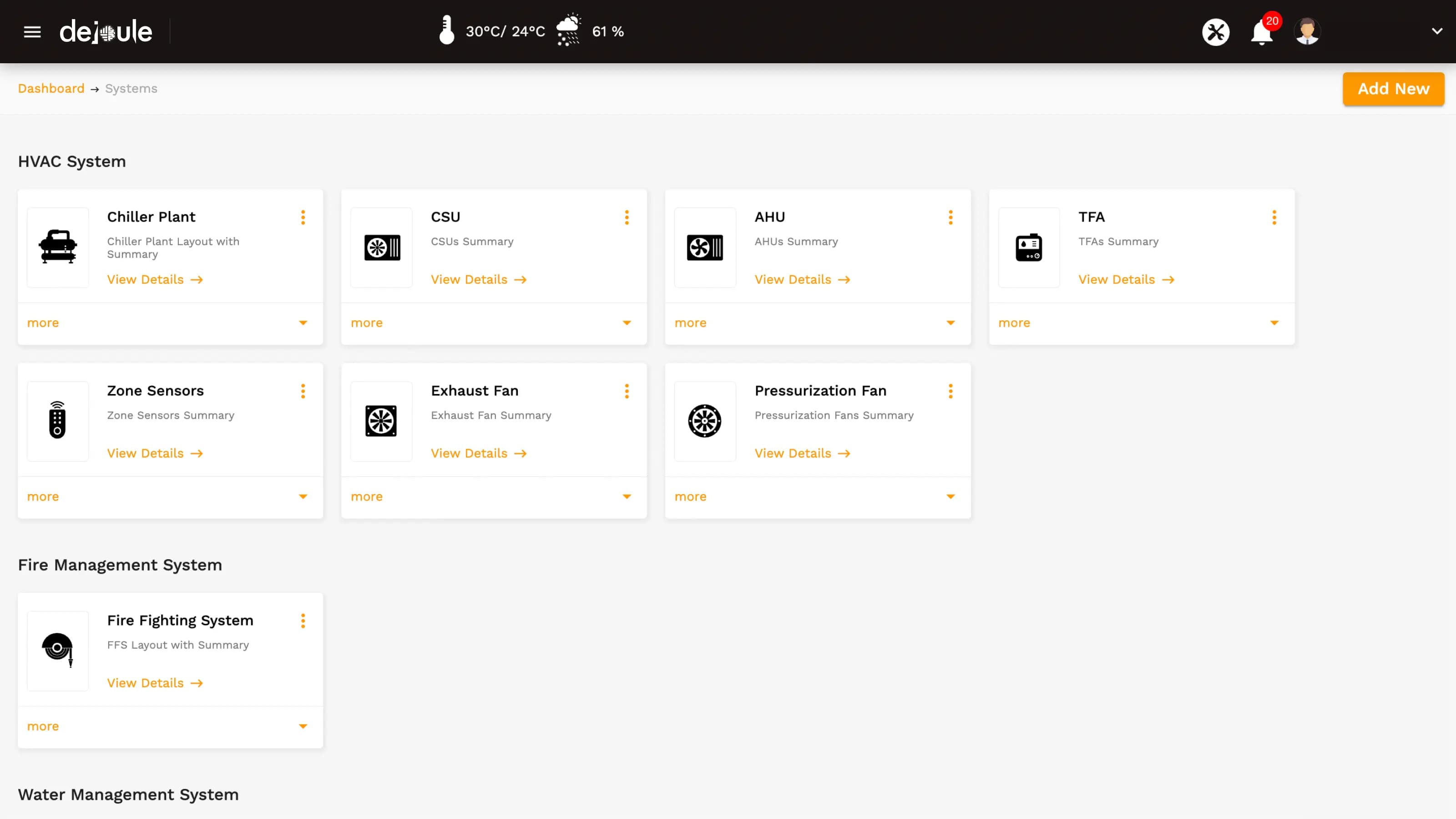

Most buildings today have some form of automation often a legacy BMS installed years ago. But automation alone does not create intelligence. A traditional BMS monitors, logs alarms, and executes predefined rules. It sees the present but does not learn from the past. It can adjust equipment but cannot predict outcomes. It responds but does not reason.

Intelligent HVAC control, by contrast, is dynamic. It does not simply run equipment; it interprets context. It uses high-resolution IoT sensors, cloud-based analytics, machine learning algorithms, and integrated building systems to determine the most efficient action for every moment. It treats a building as a living system—responding to occupancy swings, weather changes, indoor air quality, heat gain, equipment degradation, and tariff variations. The result is an HVAC environment that operates closer to its theoretical efficiency, with fewer errors, lower energy consumption, and far more stable comfort.

In practical terms, intelligent HVAC control introduces four shifts:

- From fixed logic to adaptive logic: Systems no longer follow predetermined setpoints; they adjust based on changing real-world conditions.

- From reactive maintenance to predictive maintenance: Issues are identified days or weeks before failure, reducing downtime and extending equipment life.

- From operator-led adjustments to data-driven automation: Decisions shift from manual intervention to algorithmic optimization.

- From isolated HVAC control to integrated building operations: HVAC performance becomes interconnected with lighting, air quality, access control, energy metering, and digital O&M systems.

This transition unlocks higher energy efficiency, operational stability, and compliance with global and Indian standards, including ASHRAE guidelines and ISHRAE recommendations for comfort and indoor air quality.

Pro Tip:

Real-time data loses value if uncalibrated. Ensure sensors for temperature, flow, pressure, and energy are calibrated quarterly; even small drifts can quietly erode HVAC optimization gains.

How IoT Becomes the Nervous System of Modern HVAC

IoT technology is the foundation that makes intelligent HVAC possible. It creates the digital observability that traditional systems lacked. When a chiller plant or air-handling unit is equipped with smart sensors, real-time data begins to reveal patterns that were previously invisible: low delta-T syndrome, coil fouling, AHU instability, cooling tower inefficiencies, pump imbalance, or poor valve control. Each insight becomes a lever for optimization.

IoT-enabled sensors today measure temperature, humidity, differential pressure, flow rates, energy use, fan speeds, valve positions, vibration, and CO₂ levels with extraordinary granularity. In India's rapidly digitizing buildings, these sensors are becoming as essential as electrical wiring. They form the foundation for accurate load estimation, chilled water system optimization, airside and waterside balancing, and advanced FDD (Fault Detection and Diagnostics) systems.

But sensors alone are not enough. IoT gateways and edge devices serve as the interpreters—collecting data across Modbus, BACnet, OPC-UA, and proprietary protocols, packetizing it securely, and sending it to cloud platforms. Modern gateways can run edge algorithms that allow certain optimization routines to continue even if connectivity drops—a critical capability for hospitals, airports, and data centers.

Once data reaches the cloud, its value multiplies. Cloud-based analytics platforms analyze thousands of data points per minute to identify inefficiencies, predict failures, benchmark performance across buildings, and recommend optimizations. Machine learning algorithms begin to identify daily and seasonal patterns: higher loads in the west-facing wing in May, lower cooling demand on weekends, recurring inefficiency during morning start-up, or the chiller that consistently operates at lower efficiency after maintenance.

Over time, patterns translate into control intelligence. This is where the line between building automation and building intelligence becomes sharply visible.

Machine Learning: The Brain of Intelligent HVAC Systems

Machine learning is not magic; it is pattern recognition at scale. In HVAC systems, ML algorithms continuously observe how equipment behaves under different load conditions, weather patterns, and operating strategies. They learn from this behavior to predict the most efficient configuration for the next moment.

For example, an ML model may learn that during peak humidity hours in Chennai, the cooling tower fan should operate at a specific speed to minimize chiller lift. Another model may recognize that a particular chiller's efficiency drops significantly at part load, and therefore, sequencing decisions must be adjusted. These micro-optimizations accumulate into meaningful energy savings.

Where ML becomes transformative is in predictive control. Instead of reacting to current load conditions, algorithms forecast demand. They anticipate how the system should behave five minutes, fifteen minutes, or an hour ahead. This is the opposite of how buildings have traditionally operated, where the system perpetually "chases" the load. Predictive control keeps the system ahead of the curve.

Pro Tip:

Always benchmark equipment performance against seasonal patterns. Chillers, pumps, and cooling towers behave differently across months; monthly analytics prevent creeping inefficiencies from becoming chronic by year-end.

The potential is even greater with reinforcement learning, a method where algorithms learn optimal strategies by exploring multiple possibilities. These models continuously test micro-adjustments and measure the energy impact, gradually discovering the most efficient control strategies. Reinforcement learning is the foundation of the coming generation of autonomous HVAC plants that optimize themselves without waiting for human instructions.

Remote Monitoring: From Site-Bound Operations to Digital-First Facilities

Across India, many facility teams still rely on physical presence to manage HVAC systems. Operators travel across sites, adjust parameters locally, respond to alarms manually, and interpret system behavior from fragmented logs. In a multi-site organization such as hospital chains, retail networks, airports, and corporate campuses, this model cannot scale.

Remote monitoring and control transforms operations. A single operations centre can oversee dozens or hundreds of buildings, receive real-time alerts, approve or override AI recommendations, track energy performance, and ensure compliance with thermal comfort guidelines. This digital-first model reduces site dependency, improves accountability, and enables faster response to anomalies.

For enterprises with a distributed footprint, intelligent HVAC control becomes not only an energy strategy but also an operational architecture.

The Strategic Value Proposition: Why Intelligent HVAC Matters

Energy savings are the most visible benefit, but they are not the only one and often not even the most strategic.

For large buildings in India, HVAC accounts for 40–60% of electricity consumption. Studies across Indian hospitals, IT campuses, hotels, and commercial buildings consistently show that intelligent HVAC optimization can reduce this by 15–40%. These savings directly improve profitability, especially in sectors with rising energy tariffs and tight operating margins.

But beyond cost savings, intelligent HVAC systems improve occupant comfort by stabilizing temperature, humidity, and airflow. A stable HVAC environment improves worker productivity, reduces patient discomfort in hospitals, and ensures compliance with IAQ and thermal comfort guidelines.

Predictive maintenance, another major benefit, reduces unplanned downtime. Equipment failures such as chiller trips, pump burnout, or cooling tower malfunctions can cause cascading disruptions. Intelligent systems detect early warning signs weeks in advance, converting emergency breakdowns into scheduled interventions.

At a portfolio level, intelligent HVAC systems give CXOs what traditional BMS systems never could: cross-site visibility, benchmarking, standardized reporting, and enterprise-wide performance governance. Instead of relying on anecdotal or reactive operations, organizations gain a data-backed, real-time understanding of how buildings actually perform.

Perhaps most importantly, intelligent HVAC systems advance sustainability outcomes. Buildings contribute nearly 40% of global emissions, and HVAC is the backbone of this footprint. As corporate ESG commitments intensify and India begins tightening energy disclosure and performance norms, organizations with intelligent HVAC infrastructure will be far better positioned to comply with emerging regulatory expectations, whether related to energy intensity, indoor air quality, refrigerant management, or carbon disclosure.

Pro Tip:

Remote monitoring should complement, not replace, local operational discipline. Combine digital oversight with weekly physical walkthroughs; this hybrid model is consistently the most reliable in Indian building conditions.

Why Legacy BMS Alone Is No Longer Enough

Most commercial buildings in India already have a Building Management System. However, many of these BMS installations were deployed years ago, with limited analytics, static rules, and minimal interoperability. They excel at monitoring, alarming, and basic control logic, but they fall short in four areas: adaptability, scalability, intelligence, and long-term performance tracking.

A legacy BMS cannot predict load. It cannot analyze data across multiple buildings. It cannot learn from seasonal behavior or optimize based on tariff structures. It cannot detect subtle deviations that indicate future equipment failure. It cannot benchmark performance across time or across buildings. And it cannot integrate seamlessly with modern digital O&M platforms.

Intelligent HVAC systems do not replace the BMS; they exceed it by building on top of it. The BMS becomes the execution layer, while IoT and cloud analytics become the intelligence layer. This layered architecture upgrades building automation into a scalable, future-proof platform.

This model allows buildings to integrate HVAC operations with energy metering, IAQ monitoring, lighting systems, solar PV, DG sets, access control, fire systems, and water management. With integration, a building transitions from a set of isolated systems into a coordinated ecosystem that responds to occupant needs, operates with higher reliability, and consumes far less energy.

Future Trends That Will Redefine Intelligent HVAC in India

The next decade will bring fundamental architectural shifts in how buildings operate.

One of the most significant is the move toward autonomous HVAC plants, where reinforcement learning algorithms take full control of chiller sequencing, condenser water optimization, pump control, and AHU adjustments. These plants will not require daily manual tuning; they will optimize themselves continuously.

India will also see deeper integration of HVAC systems with smart grids. As renewable energy penetration increases, buildings will be called upon to modulate their cooling loads dynamically to stabilize the grid. HVAC, being the most flexible and largest controllable load in buildings, will play a pivotal role in this transition.

Comfort will undergo a similar transformation. Instead of maintaining uniform temperatures across entire floors, hyper-personalized comfort systems will adjust micro-zones based on occupancy, activity, and individual preferences. This will increase comfort while reducing waste.

Digital twin ecosystems will enhance the way buildings are designed, operated, and retrofitted. By simulating equipment behavior, energy performance, and degradation patterns, digital twins will make long-term planning more data-driven and reduce the risk of costly retrofit errors.

Cybersecurity will become a core design principle. As HVAC systems connect to cloud platforms and integrate with enterprise networks, organizations will need robust encryption, zero-trust architectures, and continuous monitoring to ensure safe operations.

Finally, regulatory alignment will accelerate adoption. India's commitments under the Energy Conservation Act, revisions to ECBC, ISHRAE's guidance on thermal comfort, and global ESG reporting frameworks will push organizations to adopt intelligent control systems not only as a source of efficiency but as a requirement for compliance.

An Operating Model Shift, Not Just a Technological One

The shift to intelligent HVAC control is not merely an upgrade of technology. It is a rethinking of how buildings should be operated. Traditional building operations are centered on human intuition, manual adjustments, and reactive maintenance. Intelligent operations are centered on digital observability, predictive insights, automation, and continuous optimization.

This is a transition from manually run buildings to digitally governed buildings. For organizations willing to make this shift, the rewards are substantial: lower total cost of ownership, higher comfort stability, lower carbon footprint, more reliable operations, and greater resilience.

For SmartJoules, this aligns naturally with our philosophy of eliminating energy waste through engineering excellence and intelligent control. As buildings across India strive for better performance under tightening constraints, intelligent HVAC control is emerging as the most reliable pathway to efficiency, sustainability, and operational excellence.