Across most commercial buildings, whether hotels, hospitals, offices, or campuses, the biggest drain on time isn't troubleshooting or firefighting. It's the routine, everyday operational tasks that soak up hours of attention.

Reset an AHU setpoint.

Schedule pump cycles.

Trigger a tower fan to ramp up because the ambient temperature just crossed a threshold.

Switch a system to night-setback mode.

Send an alert when a filter pressure drop crosses limits.

These actions are simple, but because they happen dozens of times a day, they consume disproportionate bandwidth for your facility team.

And here's the industry reality: even the most sophisticated buildings continue to run on manual routines because the automation layer has not evolved.

For decades, 'automation' inside buildings meant hardcoded logic buried deep within a traditional on-premise BMS. Any change, no matter how trivial, required vendor intervention. A technician would need to connect to the system, rewrite blocks of control logic, test them, and ensure the change didn't break existing sequences. The result? Facility teams became dependent on external specialists for even routine adjustments. SOPs aged faster than the building. And operational agility, the one thing buildings desperately need, was structurally impossible.

In other words, automation remained frozen while the building kept changing.

The real limitation: Automation that cannot evolve

A building's operational behavior must adapt continuously: to occupancy, to load variability, to weather shifts, to equipment ageing, and to the realities of how teams work across multiple shifts.

But traditional BMS logic doesn't adapt. It is rigid by design. Once commissioned, the programming stays largely untouched because modifying it is difficult, expensive, and risky.

This leads to patterns that every Chief Engineer has seen firsthand:

- Operators override controls because sequences don't match real-world conditions.

- SOPs drift across shifts because logic cannot be fine-tuned quickly.

- Energy waste accumulates because conditions change faster than the BMS can respond.

The limitation isn't the equipment. It's the programming model. Automation that cannot evolve with the building ceases to be automation. It becomes a bottleneck.

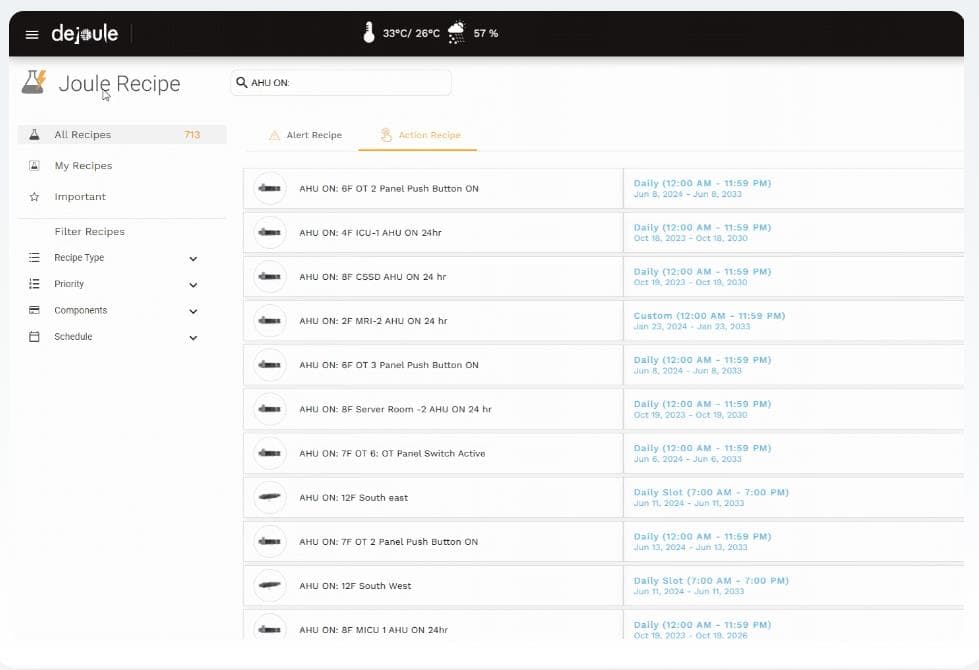

Introducing Joule Recipes: Automation re-engineered for modern facilities

Joule Recipes changes this paradigm completely.

It replaces rigid programming with an intuitive, IFTTT-based automation layer built directly into DeJoule, enabling facility teams themselves to design, deploy, and refine operational logic with ease.

Instead of coding, operators simply select conditions and actions the way they would set up automations in apps they use every day. Drag-and-drop logic blocks. Pre-built templates. Clear, natural-language triggers. No risk of breaking backend sequences. No vendor dependency. No waiting for upgrades or technical support.

The core idea is simple yet transformational: Automation should belong to the people who run the building, not the people who programmed the BMS years ago.

Joule Recipes shifts operational control back into the hands of Chief Engineers and facility teams, where it always belonged.

What Joule Recipes lets you achieve

With Joule Recipes, any utility integrated with DeJoule across high-side and low-side systems can be automated through condition-based logic or scheduled routines. But the power is not in the number of systems; it is in the flexibility of the automation itself.

Teams can automate repetitive actions that consume hours every week. They can build sequences that react instantly to real-time conditions. They can enforce SOP consistency without manual intervention. And they can shape operational behavior in a way that mirrors how the building actually performs rather than how it was originally designed on paper.

For example, a Chief Engineer can configure a rule that automatically resets condenser water temperature the moment outdoor wet-bulb conditions shift, something that traditionally required vendor programming and often remained untouched for entire seasons.

Or an operator may set a rule that increases AHU airflow automatically whenever return air temperature drifts beyond a defined tolerance band, ensuring comfort without continuous manual adjustments.

These are not theoretical capabilities. They are practical, everyday automations that eliminate repetitive effort, reduce human error, and enhance operational responsiveness.

Why this shift matters operationally and technically

When automation becomes accessible, the operations team gains a different kind of control—not just over equipment, but over the building's behavior itself.

Joule Recipes enables a facility to:

- Respond faster to load changes and environmental fluctuations, since logic can be tuned instantly.

- Operate more consistently, because automated routines execute the same way across all shifts.

- Reduce manual dependency, freeing operators to focus on diagnostics, preventive maintenance, and system health.

- Adapt SOPs continuously, ensuring the building does not rely on outdated commissioning logic.

- Evolve operational efficiency, because adjustments no longer depend on service cycles or programming expertise.

This is not 'another feature' inside a BMS. It is a fundamental redesign of how operational intelligence is created, deployed, and refined inside a facility.

Automation stops being static and becomes dynamic.

It stops being intimidating and becomes intuitive.

It stops being a vendor-controlled layer and becomes an operational asset.

The real differentiator: Who owns the automation?

With traditional systems, automation belongs to the OEM.

With Joule Recipes, automation belongs to the facility.

This distinction defines the future of building operations. As buildings grow more complex, as loads become more variable, and as sustainability demands rise, the only viable automation model is one that empowers the people closest to the operations, not the people farthest from it.

Joule Recipes is built on this principle.

And that is what makes it different.

Ready to automate what truly matters?

If your daily operations still rely on manual routines or rigid BMS programming, Joule Recipes gives your team the ability to automate with precision, confidence, and complete independence.

To see how leading facilities are using Joule Recipes to redefine everyday operations, connect with our team.