Chiller plants power the comfort, operations, and resilience of India’s built environment. Whether in hospitals, IT hubs, commercial towers, airports, or industrial campuses, they operate relentlessly beneath the surface, consuming more electricity than any other building system. In India’s warm and humid climatic zones where cooling is a year-round burden this cost is magnified. And yet, across thousands of plants we’ve studied, the same truth repeats: most chiller plants run significantly below their optimal efficiency.

This is not because India’s HVAC equipment underperforms. Nor because facilities lack automation. The real challenge lies in day-to-day operations: drifted sensors, poor sequencing, static BMS logic, unpredictable weather patterns, high humidity, load variability, and maintenance gaps. ISHRAE’s guidelines repeatedly highlight that chilled-water systems offer India’s biggest energy-saving opportunity but only if operated dynamically. As we explained in our guide on why buildings must stop ignoring their chiller plant, inefficiency is rarely dramatic. It accumulates silently, every hour of every day.

Today, with data availability, modern optimization algorithms, and reinforcement learning, Indian buildings can reclaim massive performance losses that were once considered inevitable. Chiller plants no longer need to run on fixed logic; they can operate as adaptive, self-correcting systems aligned with India’s climate and load realities. This guide integrates ISHRAE best practices, India-centric field findings, SmartJoules’ on-ground experience, and advanced AI methodologies to illustrate exactly how optimization works—and why it is no longer optional.

Why Chiller Plant Optimization Matters in India

India’s cooling demand is rising at one of the fastest rates globally. Dense urban developments, expanding digital infrastructure, and growing commercial real estate all place heavier loads on mechanical cooling. Electricity tariffs in states like Maharashtra, Tamil Nadu, Karnataka, and Delhi have steadily risen, and buildings with poor HVAC efficiency experience disproportionately higher operating costs.

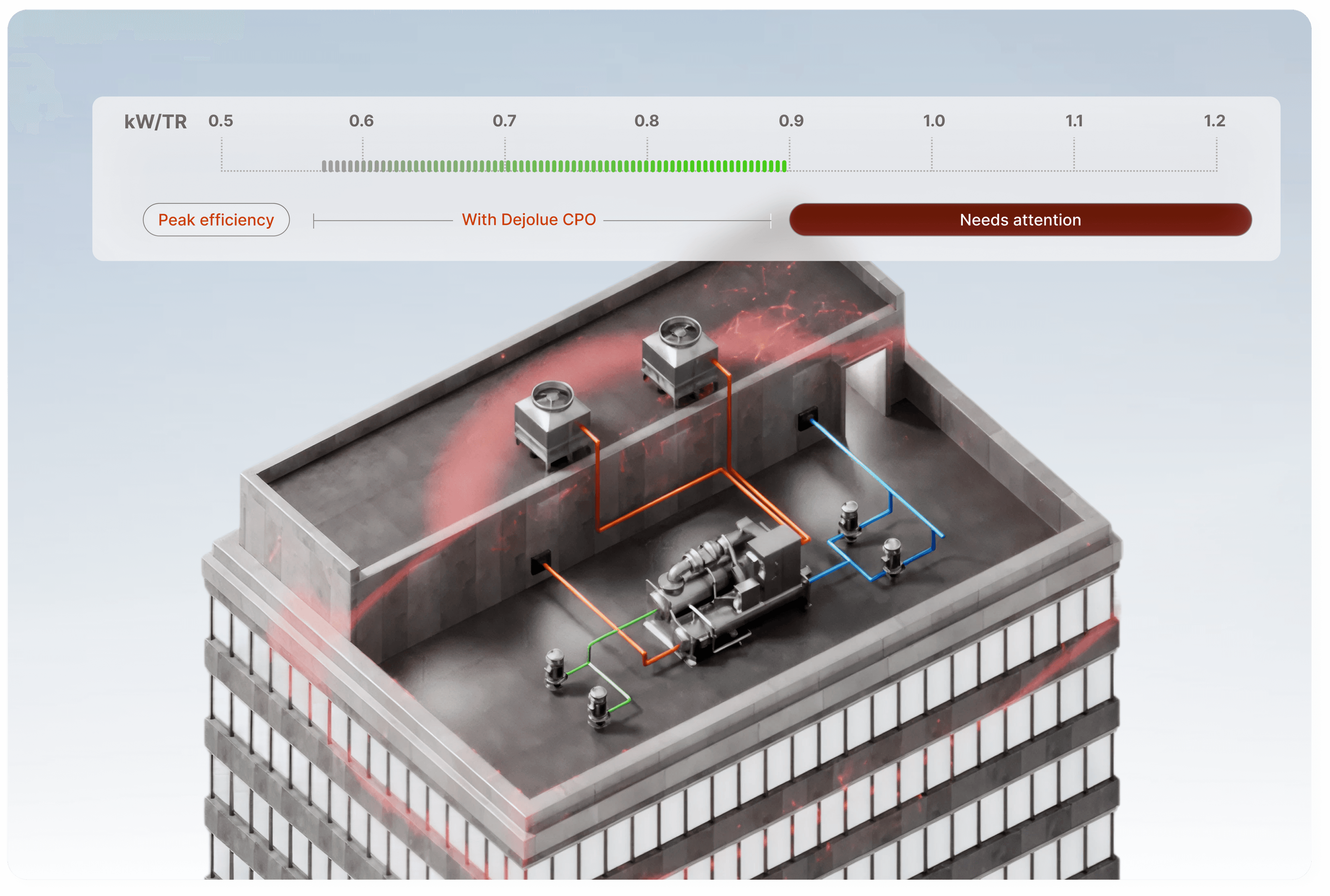

Most Indian plants today operate between 0.9 and 1.2 kW/TR, while optimized plants routinely perform at 0.55 to 0.70 kW/TR. This performance delta reflects significant financial and environmental opportunity, especially in facilities operating 10–24 hours per day.

At the same time:

- Hybrid work patterns create unpredictable occupancy profiles

- Monsoon-driven humidity affects cooling tower behavior

- Seasonal dust accelerates fouling

- Rising ESG pressure demands measurable reductions in energy and carbon

In our exploration of how existing buildings can maximize chiller plant efficiency, we showed that nearly every Indian building has at least a 20–40% technical efficiency reserve waiting to be unlocked.

Chiller plant optimization is not just an engineering best practice, it is a financial imperative and a sustainability obligation.

Common Inefficiencies in Real-World Chiller Plants

Across Indian commercial buildings, inefficiency rarely appears as a single glaring problem. It hides in the margins, in drifting behaviors that slowly compound into massive energy waste. Heavy technical diagnostics consistently reveal these patterns:

Delta-T Degradation (India's Most Common Problem)

Plants designed for a 6–7°C ΔT often operate at 3–4°C. This collapse forces chillers, pumps, and coils out of their efficiency sweet spots.

Key contributors:

- Oversized or leaking control valves

- Fouled AHU coils and heat exchangers

- Improper chilled-water setpoints

- Unbalanced hydraulics and unstable DP control

ISHRAE audits estimate that delta-T issues alone can add 20–35% extra energy consumption.

Pro Tip:

A stable ΔT is the single strongest indicator of plant health. Track it hourly if it drops below design, investigate valves, coils, or balancing immediately before energy losses multiply.

Condenser-Water Inefficiencies

Cooling towers in India face high dust load, variable water quality, and humidity swings. As fill fouls or fans run inefficiently, the condenser water temperature rises.

Consequences:

- Every 1°C rise in condenser water temp increases chiller power by 2–3%

- Tower performance drops sharply during peak humidity

- Improper CT fan logic leaves energy savings unrealized

Sequencing Inefficiencies

Many Indian operators run extra chillers “just to be safe,” especially at night or during transitional loads.

This leads to:

- Low part-load efficiency

- Higher cumulative compressor energy

- Pump operation exceeding required flow

In our analysis of how a chiller plant optimizer unlocks peak energy savings,we show that improper sequencing is one of the largest sources of preventable energy waste.

Best Practice: Never run extra chillers "just to be safe." Validate load, check real-time efficiency, and use data-driven sequencing unnecessary chillers can silently add 15–25% energy waste.

Sensor Drift and Missing Data

Most Indian plants lack calibration routines. Even a 0.5°C drift in sensors or 10% error in flow meters destabilizes entire control strategies.

Fouling and Reactive Maintenance

Dust, water quality issues, and inadequate cleaning practices degrade coils, tubes, and tower fill. Without early detection, performance slowly deteriorates over months.

These inefficiencies are symptoms of a deeper issue: systems built for dynamic operation controlled by fixed, outdated logic.

The Components That Shape Plant Performance

A chiller plant’s behavior emerges from the interaction of its subsystems. When diagnosing performance, ISHRAE emphasizes studying the plant holistically rather than component-by-component. Several components exert disproportionate influence on efficiency:

Chillers

Their performance depends directly on the temperature difference between chilled-water leaving temperature and condenser-water entering temperature. Key factors affecting lift include:

- Delta-T collapse

- High condenser approach

- Fouled tubes

- Inaccurate water-temperature sensors

- Poor refrigerant charge or aging compressors

Cooling Towers

As India faces dust-heavy conditions and high humidity, towers are particularly vulnerable to fouling. Performance depends on Wet-bulb alignment, Airflow uniformity, Fan speed response, Fill condition, Basin temperature dynamics.

Pumps

Pump energy varies with the cube of RPM. That means even small inefficiencies create large losses.

Typical failure modes include:

- Poor DP setpoint logic

- Excessive minimum speed limits

- Running more pumps than needed

Valves, Coils, and Controls

A leaking two-way valve can collapse delta-T across the building. Fouled coils can artificially inflate the load on chillers. Sensors with drift distort optimization decisions.

In short, the physics is simple: small inefficiencies cascade across the plant. Optimization requires harmony, not isolated tuning.

Why Traditional BMS Logic Fails

Most Indian buildings still operate their chiller plants through BMS logic specified years ago. While the BMS provides monitoring and basic control, it fundamentally lacks the intelligence required for dynamic optimization.

Limitations include:

- Static rules that cannot adapt to weather, load, or equipment aging

- No real-time efficiency calculations

- No coordination between chillers, pumps, and towers

- No predictive capability

- No self-learning

- No automated correction when plant behavior drifts

This creates a performance gap described in our breakdown on smart automation beyond traditional BMS limits:BMS can control, but it cannot optimize.

Even expert operators cannot manually adjust setpoints every 5 minutes based on real-time wet-bulb readings, occupancy variations, valve positions, load forecasts, and chiller curves. The human mind simply can’t process this many variables continuously.

This is where AI steps in, not to replace humans, but to augment them with constant computational intelligence.

How AI and Reinforcement Learning Transform Optimization

Machine learning introduces the adaptiveness Indian plants need. Instead of fixed logic, AI models interpret real-time data, predict outcomes, and choose optimal actions.

Why AI Works Better in Indian Climates

- Wet-bulb swings during monsoons require dynamic CT fan response

- Hybrid occupancy makes load behavior unpredictable

- High dust load accelerates fouling, requiring predictive maintenance

- Energy tariffs and demand charges vary, affecting operating cost strategy

AI observes these patterns continuously.

How Reinforcement Learning (RL) Operates Inside a Plant

RL doesn’t rely on a static model it learns directly from the plant’s live behavior.

Key RL capabilities include:

- Discovering hidden patterns (e.g., how delta-T improves with certain pump speeds)

- Predicting load based on occupancy and historical trends

- Adjusting chilled-water and condenser-water setpoints in real time

- Finding the optimal balance between chiller lift, pump energy, and CT fan energy

- Self-correcting when environmental conditions change

Our detailed exploration in how DeJoule's reinforcement learning is making chiller plants smarter shows that RL improves continuously—it becomes more efficient month after month.

Practical Benefits of RL Optimization

- Higher chiller loading where they perform best

- Lower lift through smarter CT operation

- Precise pump modulation

- Fewer chillers running at any time

- Rapid recovery from operational drift

This is the intelligence that traditional automation lacks.

The Role of Digital O&M in Sustained Efficiency

No optimization system can function properly without reliable physical conditions. This is where Digital O&M becomes indispensable.

Digital O&M Strengthens Optimization Through:

- Real-time dashboards for kW/TR, lift, delta-T, approach temperature

- Automatic fault detection and diagnostics (FDD)

- Predictive maintenance alerts

- Sensor validation and drift detection

- Performance benchmarking across seasons

- Early detection of fouling trends

- Operator accountability and audit trails

ISHRAE’s O&M guidelines emphasize that efficiency is not an event; it is a disciplined process. Our article on what will make your building ready for chiller plant optimization outlines these requirements in depth.

Digital O&M ensures that months of optimization do not unravel due to avoidable maintenance lapses.

Best Practice:

Treat fouling as a predictable event, not a surprise. Trend tower approach, chiller lift, and coil ΔP weekly catching early drift prevents months of silent efficiency loss.

The Future of Autonomous Chiller Plants

India’s grid, climate, and sustainability context make autonomous HVAC systems inevitable. The next wave of chiller plants will be:

- Self-learning — RL-driven control that adapts daily

- Grid-interactive — adjusting loads to avoid peak tariffs

- Predictive — forecasting failures and loads

- Low-carbon — optimizing not just for energy, but emissions

- Digitally resilient — real-time monitoring of every subsystem

- Integrated — using Digital Twins to simulate future operating states

Chiller plants will shift from reactive control to anticipatory intelligence.

Conclusion

Chiller plant optimization is India’s largest and most immediate energy-saving opportunity. It enhances comfort, reduces costs, extends equipment life, and dramatically lowers carbon emissions. More importantly, it transforms buildings from reactive systems into intelligent, adaptive assets.

Buildings relying solely on BMS logic will continue to lose efficiency daily. Buildings that adopt AI-driven optimization, reinforcement learning, and Digital O&M will lead India’s next chapter of sustainable infrastructure.

The question is no longer whether optimization is necessary.

The real question is: How much is your building losing every month you delay it?

SmartJoules is committed to empowering India's built environment with the intelligence and tools needed to operate at peak performance—not just occasionally, but continuously.

FAQ: Chiller Plant Optimization

Q1. What is chiller plant optimization?

Chiller plant optimization is the continuous process of reducing the energy consumed by chillers, pumps, and cooling towers by dynamically adjusting setpoints, flows, and sequencing based on real-time data, ISHRAE guidelines, and advanced control algorithms like machine learning and reinforcement learning.

Q2. What is DeJoule CPO (Chiller Plant Optimizer)?

It is SmartJoules' advanced, AI-driven optimization engine that continuously improves the performance of a building's chiller plant in real time. It replaces static, rule-based control with intelligent, adaptive, data-driven decision-making that minimizes total plant energy consumption while ensuring comfort and reliability.

Q3. Why do most Indian buildings operate their chiller plants inefficiently?

Inefficiency arises from delta-T degradation, fouled cooling towers, incorrect sequencing, sensor drift, fixed BMS logic, and highly variable Indian climate conditions such as monsoon humidity and dust load—all of which static control systems cannot handle.

Q4. What role does AI play in optimizing chiller plants?

AI models analyze plant behavior, predict load, estimate equipment efficiency, and recommend or execute optimal setpoints. Reinforcement learning goes further by self-learning from real plant interactions and improving continuously.

Q5. What is delta-T degradation, and why is it harmful?

Delta-T degradation occurs when the temperature difference between CHW supply and return collapses. It forces pumps and chillers to work harder, increasing energy use by 20–35%.

Q6. Why is traditional BMS not enough for optimization?

BMS uses static rules that do not adapt to weather, load variations, fouling, or aging equipment. It lacks predictive intelligence, real-time optimization logic, and the ability to coordinate system components holistically.

Q7. How does reinforcement learning optimize chiller operations?

Reinforcement learning learns from live plant behavior, adjusts decisions based on outcomes, predicts thermal patterns, and continuously improves setpoints, pump speeds, and sequencing logic for the lowest total kW without compromising comfort.

Q8. What is the role of Digital O&M in maintaining efficiency?

Digital O&M ensures sensor accuracy, detects faults early, monitors performance KPIs, and prevents operational drift—allowing optimization algorithms to operate under reliable conditions.

Q9. Do buildings need new equipment to achieve high efficiency?

Not all buildings. Most buildings unlock massive savings by optimizing the control layer and improving O&M discipline. Many of our projects achieve 20–40% savings without replacing chillers or towers.